Bevelling (beveling in the US), sometimes referred to as chamfering, is a crucial process in metalworking that involves creating a sloping edge on a plate or pipe. This chamfer, or angled cut, is necessary to prepare the welding edge, particularly for materials with a thickness exceeding 5 mm. Bevelling, or chamfering, prior to welding ensures enhanced strength and stability in the final construction.

PURMILL

➜ High-quality surface finish of the bevel

➜ Bevelling of the toughest alloys

➜ System for compensating irregularities

ULTRAMILL

➜ Plates up to 120 mm thick

➜ Automatic feeding system

➜ Digital displays

ULTRAMILL ROTO

➜ Bevelling of very hard alloys including Hardox and Duplex

➜ Adjustable for beveling both top and bottom sides

➜ Speed control of the tool and feeding

SQUAREMILL

➜ Automatic movement along the plate

➜ Dual system for eliminating uneven surfaces

➜ Integrated handling trolley

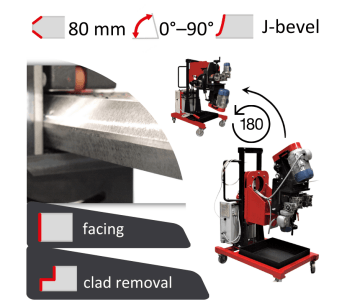

HURDMILL

➜ Supports J-bevel geometry

➜ For very hard alloys

➜ Automatic feeding system

LITEMILL

➜ Mobile and light machine

➜ Excellent surface quality of the bevel

➜ System for compensating irregularities

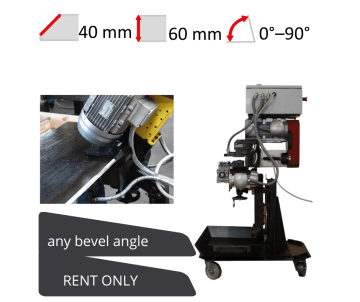

SPEDANGLE

➜ Easy change of bevel angle setting

➜ Low noise operation

➜ Possibility of beveling pipes

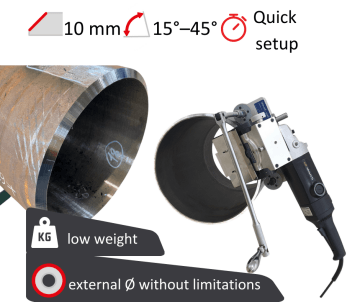

SHEELITE

➜ Mobile and lightweight

➜ High beveling speed

➜ Chamfering of the outer edge pipes

SHEEZER

➜ Mobile and lightweight

➜ For flat or slightly curved plates

➜ Capability to bevel the bottom side of plates

ROTOSHEEZ

➜ Integrated chassis with rotator

➜ Easy bevel angle adjustment

➜ For flat or slightly curved plates

MAXCLINE

➜ Easy adjustment of bevel angle and width

➜ Overload and vibration protection

➜ Quick and easy insert replacement

RADIMAX

➜ Easy operation and low weight

➜ Equipped with electric speed control

➜ Can be used on pipes and cutouts

Handmill / Handmill Inox

➜ Face milling

➜ Equipped with electric speed control

➜ Cutting depth control

VEEZY

➜ Optional automatic feeding system available for purchase

➜ Capable of beveling radius R2, R3, and R4

VEERIO

➜ Suitable for machining small parts

➜ Ability to process various materials

➜ Optional material feeding system available

INCURV

➜ Capable of machining different materials

➜ Adjustable speed control

➜ Optional automatic feeding system available

SWIFTURN

➜ Pipe diameter 254–812 mm and 610–>flat plates

➜ Beveling speed of up to 1 m/min

➜ Bevel angle from 0°–45°

FEADER

➜ Automatic feeding system

➜ Suitable for machining small parts

BENCHMILL

➜ Easy sliding and adjustment of bevel width

➜ Can bevel high-strength materials

NIDBUR

➜ Very low weight

➜ For straight or curved sheets

➜ Deburring

CB 01-03

➜ Radius on edge

➜ Pneumatic drive

➜ Deburring