HURDMILL | versatile machine with extreme performance

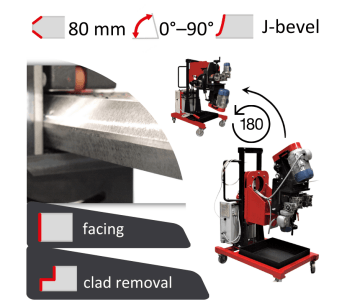

Supports J-bevel geometry

Automatic feeding system

Suitable for

Available in upside-down version for bottom-side plate bevelling

Technical parameters

Maximum bevel width: | 80 mm |

|---|---|

Bevelling angle: | 10°–70° (J-bevel 0°–30°) |

Plate thickness: | 6—120 mm |

Bevelling speed: | 0—1.5 m/min |

Motor Power: | 4 kW |

Motor idle speed: | 820 rpm |

Voltage: | 400 V/50 Hz |

Tooling: | 80 mm diameter face cutter - 9 changable inserts |

Net weight of the machine: | 288 kg |

Machine weight (incl. trolley): | 300 kg |

HURDMILL

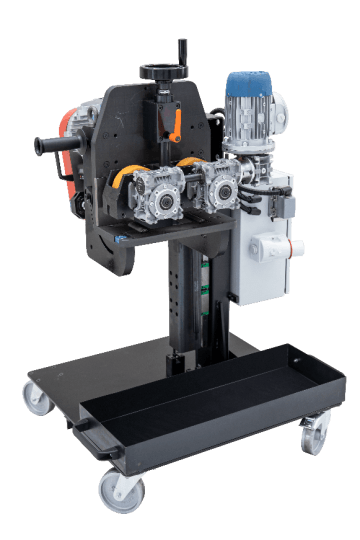

HURDMILL is an extremely powerful beveling machine designed for high material removal. The machine is equipped with a high-speed rotary milling head and is intended for beveling plates with a thickness of up to 120 mm and a bevel width of up to 80 mm.

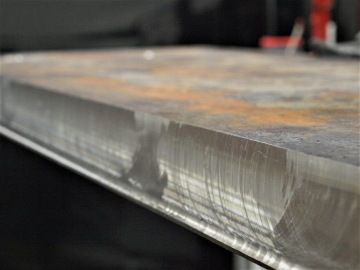

The front-facing cutter with 9 carbide inserts is optimized for high material removal. This allows for a single pass diagonal beveling of up to 20 mm on standard steels. The milling technology ensures that the surface of the bevel is smooth and requires no further processing. The bevel angle can be easily adjusted by tilting the milling unit within a range of 10° to 70°.

The beveling machine is mobile, with its own chassis, enabling it to move along the material and be easily relocated between workstations. The working height of the machine can be adjusted within a range of 804 to 1,054 mm. Once initially guided onto the plate, the beveling machine is equipped with an automatic feed system under the supervision of the operator. For smaller pieces of material, the beveling machine can independently feed and bevel without the need for physical exertion from the operator.

Using special carbide inserts, the machine can process nearly all types of steel and alloys, such as Hardox, Duplex, Inconel, and similar materials. An inverted version of the machine is also available for beveling the lower edges of plates without the need for rotation.

OPtional Accessories

Ball unit table, ball unit track

Roller supports

Magnetic chip collector

Case study: J-bevel

J Bevel Case Study: Achieving Precision with J-Bevels using HURDMILL mobile beveller.

AlternativE products

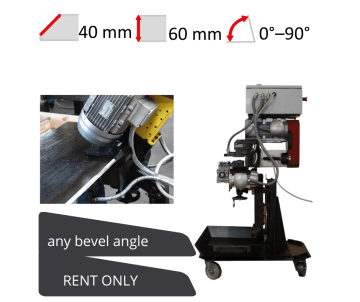

PURMILL

➜ High-quality surface finish of the bevel

➜ Bevelling of the toughest alloys

➜ System for compensating irregularities

SQUAREMILL

➜ Automatic movement along the plate

➜ Dual system for eliminating uneven surfaces

➜ Integrated handling trolley

ULTRAMILL ROTO

➜ Bevelling of very hard alloys including Hardox and Duplex

➜ Adjustable for beveling both top and bottom sides

➜ Speed control of the tool and feeding

Contact us with a request or question

Our Team of experts is here for you every working day.