PURMILL | Compact high-speed beveller

Mobile and versatile machine

With angle adjustment and plate detection

High-quality surface finish of the bevel

Bevelling of even the toughest alloys

Automatic feeding system

System for compensating irregularities

Technical parameters

Maximum bevel width: | 50 mm |

|---|---|

Bevelling angle: | 15°–60° |

Plate thickness: | 6—60 mm |

Bevelling speed: | 0—1.5 m/min |

Motor Power: | 4 kW |

Motor idle speed: | 820 rpm (optional 350–820 rpm) |

Voltage: | 400 V / 50 Hz, 3-phase |

Tooling: | 80 mm diameter cutter with 9 changeable inserts |

Net weight: | 143 kg |

Machine weight (incl. trolley): | 210 kg |

PURMILL

PURMILL is a powerful plate beveling machine equipped with a high-speed rotary milling head fitted with nine carbide inserts. It handles beveling on tough materials such as Hardox, Weldox, Inconel, and titanium. The machine supports plate thicknesses from 6 to 60 mm and bevel widths up to 50 mm, with stepless angle adjustment from 15° to 60° by tilting the entire milling unit. The feed rate reaches up to 1.5 m/min, and the milling process produces a smooth surface finish across straight and even some curved edges with a large radius.

Thanks to an automatic height adjustment system using gas struts, PURMILL adapts to variations in plate height during operation, preventing misalignment or snagging. A built-in sensor stops the milling head at the end of the plate for added safety. The machine moves along the material on two driven wheels and includes a redesigned trolley with integrated chip collection. An upside-down version is also available for beveling bottom edges without rotating the plate.

The lifespan of the carbide inserts varies depending on the material of the beveled plates, ranging from approximately 50 to 200 meters per side.

OPtional Accessories

Ball unit table, ball unit track

Roller supports

Magnetic chip collector

ALTERNAtive products

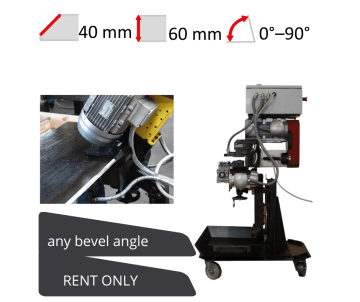

HURDMILL

➜ Supports J-bevel geometry

➜ For very hard alloys

➜ Automatic feeding system

SQUAREMILL

➜ Automatic movement along the plate

➜ Dual system for eliminating uneven surfaces

➜ Integrated handling trolley

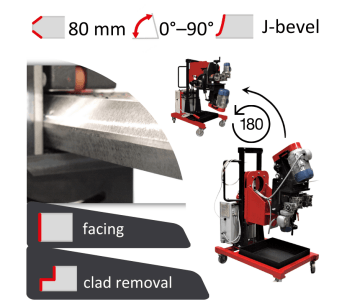

ULTRAMILL ROTO

➜ Bevelling of very hard alloys including Hardox and Duplex

➜ Adjustable for beveling both top and bottom sides

➜ Speed control of the tool and feeding

Contact us with a request or question

Our Team of experts is here for you every working day.