Not All J-Bevels Are the Same: When the Standard Isn’t Enough

Standard J-bevel vs. Offset J-bevel

Following a request from a major international customer — a welding company specialising in industrial solutions — we explored an advanced beveling solution.

In many cases, a standard J-bevel milling head is all that’s needed. This type of J-prep is commonly used for weld edge preparation on thick plates, delivering precise, repeatable results without any special machine modifications.

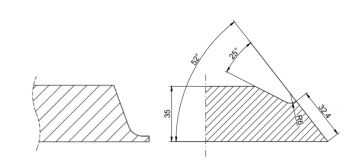

However, there are situations where the standard setup simply isn’t enough. A typical example is the offset J-bevel – a special variation where the bevel is shifted relative to the plate edge.

Thanks to our ability to provide custom machine configurations, we can adapt the equipment to match exact requirements for angle, depth, and offset. This ensures:

Perfect match to the technical drawing, essential for high-quality welding

High accuracy even with complex profiles

Compatibility with a wide range of materials, including stainless steel and high-strength alloys

Bevels prepared in this way ensure that subsequent welding is faster, more consistent, and requires less filler material.

To achieve the required result in this project, we carried out a special modification of the ULTRAMILL machine for an offset J-bevel.

By combining the custom ULTRAMILL modification with precise machine settings, we successfully achieved the required special offset J-bevel, fully in line with the customer’s technical drawing.

If you’re facing similar challenges in beveling thick plates, Contact us today to discuss your application.

contact us with a request or question

Our team of bevelling professionals is here for you every working day.

We answer your questions within 24 hours.